Mr. Y.V. Ramana Reddy, Student of MLR Institute of Technology, Department of Mechanical Engineering has participated in Athletics (200mts) duing ARENA 2020 at Bits Pilani, Hyderabad Campus between 23rd – 26th January 2020.

Mr. Y.V. Ramana Reddy, Student of MLR Institute of Technology, Department of Mechanical Engineering has participated in Athletics (4 x 100mts) duing Vignan Mahotsav – 2020 at Vignan’s Lara Institute of Technology & Science.

Mr. Y.V. Ramana Reddy, Student of MLR Institute of Technology, Department of Mechanical Engineering has participated in Relay (4 X 4) duing ARENA 2020 at Bits Pilani, Hyderabad Campus between 23rd – 26th January 2020.

Mr. Y.V. Ramana Reddy, Student of MLR Institute of Technology, Department of Mechanical Engineering has participated in 4 X 400M duing Reliance Foundation College Athletics 2019-20, at Mumbai.

M.Srinath, Student of Department of Mechanical Engineering has participated in “LINE FOLLOWING BOT”, as part of “ELAN AND NVISION 2020” at IIT Hyderabad from 14th – 16th February 2020

M.Srinath, Student of Department of Mechanical Engineering has participated in “ROBO SOCCER”, as part of “ELAN AND NVISION 2020” at IIT Hyderabad from 14th – 16th February 2020

M.Srinath, Student of Department of Mechanical Engineering has participated in “DTMF RACE”, as part of “ELAN AND NVISION 2020” at IIT Hyderabad from 14th – 16th February 2020

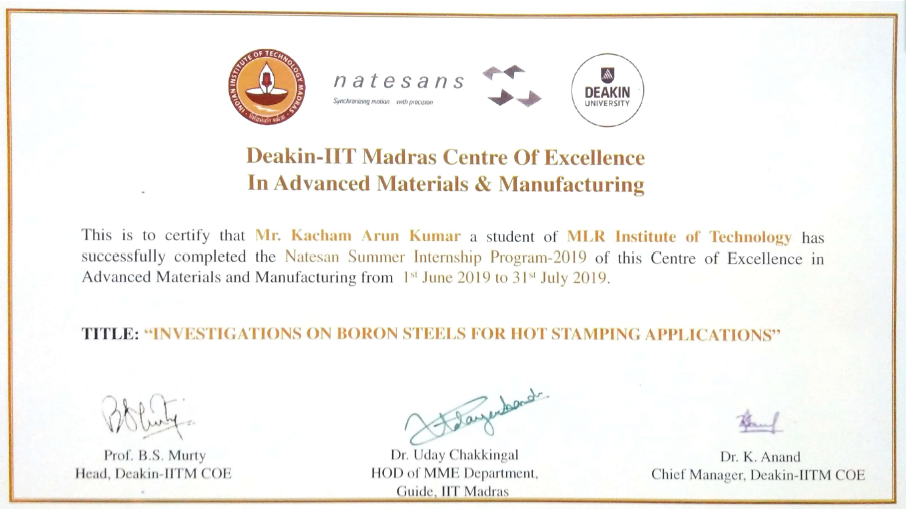

Natesan Summer Internship Program-2019

Mr.K.Arun Kumar, 17R25A0341 student of Mechanical Engineering Department has undergone prestigious internship at Materials & Manufacturing Centre of Excellence, IIT Madras under Natesan Summer Internship Program-2019 from 1st June 2019 to 31st July 2019.

I’MPACT, Mechanica ’19 Flagship Event’s Problem Statement

Organised by Mechanical Engineering Association, IIT Madras in association with RUTAG, IIT Madras and SELCO Foundation.

Students of Department of Mechanical engineering bagged first prizes in various competitions involving innovative and challenging stages in Concept generation, Detailed design and Prototyping. The details of various challenges are presented below:

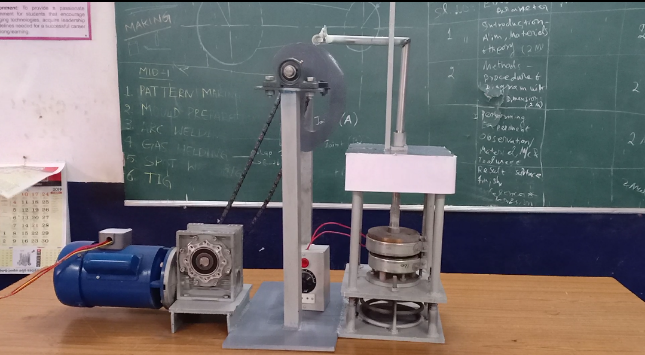

KHOA MAKING MACHINE WITH INVERTED STIRRING MECHANISM

Khoa is generally manufactured in jacketed kettles, which has several disadvantages like poor and inconsistent quality and limited shelf life of about 5 days at 30°C.Most attempts made for up-gradation of the technology of khoa are directed towards mechanization of the process and developing continuous khoa making plants has developed mechanized conical process vat for preparation of khoa. It consists of a stainless steel conical vat with a cone angle of 60° and steam-jacket partitioned into 4-segments for efficient use of thermal energy and less heat loss. Due its batch type of operation, it is suitable only for making limited quantities of the product.

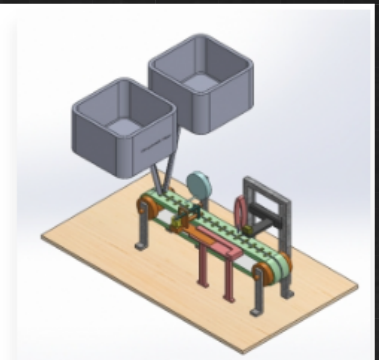

GARLAND MAKING MACHINE

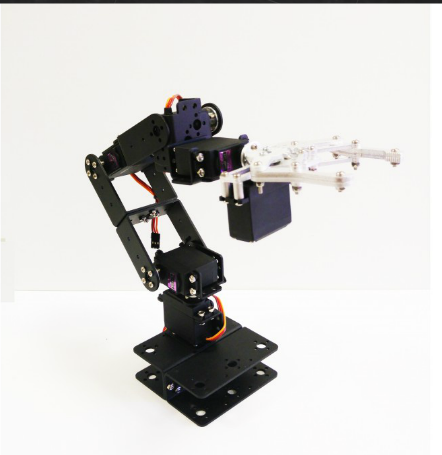

The automated garland machine have robotic arm which places the flowers on the conveyor belt, with moment of the conveyor belt the flowers move to stitching section, the flowers moving on a strip are stitched together to make a flower garland. The idea is to implement a fully automatic machine which works with the combination of robotic arm and sewing machine. Robotic arm works on the commands given through the computer programming using Embedded-C. The main objective of the robotic arm is to place the flowers on the conveyor belt.

SOLAR POWERED SUGAR CANE JUICER MACHINE

The regular model of a Sugarcane juicer machine runs with the flywheel and spur gear mechanism. But herein we changed the spur gear mechanism to straight bevel gears mechanism. Comparing to the existing model which runs on the spur gear mechanism includes heavy load with producing low amount of torque. Financially also the machine equipment is also costlier. Coming to the innovated design, the there is a decrease in weight of machine since flywheel mechanisms are completely replaced with bevel. As we are also utilizing the solar energy with a conversion of DC to AC power by the inverter with 3kw capacity reduces the usage of electricity consumption.

PAPER PLATE MAKING MACHINE

Usually the present existing machines uses hydraulic power as their working force (or) load for giving the shape to the paper. We came up with an idea of using cam and follower mechanism as the mode of transmission of force (or) load. It will reduce the cost of the machine as there is no hydraulic power used and this is a solar powered machine, so, there is no need of electric power and the maintenance cost will also be going down. The solar energy is stored in a battery taken from the solar panel which will be giving power supply to motor and the motor will be supplying power to cam shaft. Due to the shape of cam, the follower will be reciprocating, that will in-turn make the upper die free fall on the lower die and the paper plate making process is completed.

HYDRAULIC BAILING MACHINE

The machines used to compress the scrap cardboard, plastics and papers use electric power as the source combined with the several mechanisms. These machines are expensive which limits their usage to the upper fraction of the local scrap businessmen. Further, a number of people are perplexed when doing a one-time investment on this electrically run automatic machine. Instead the manual labor is required in our design and the requirement of electricity is gone. A hydraulic fluid will perform the work based on Pascal’s law. It consists of a huge vertical column with 4 cylinders and pistons. Each cylinder is connected to a tube which merges into a single tube. The piston heads are adhered to a plane block of rigid material. The main tube is then connected to a small cylinder and piston with a stopping mechanism and another tube emerges from the piston and finds its way in the fluid reservoir. When piston is given a reciprocating motion, then the fluid from the reservoir comes to the tube and begins filling the 4 cylinder pushing down the rigid material. The stopping mechanism stops the fluid from going again in the reservoir. This will produce a downward motion of the pistons and comparison process will occur. The reciprocating motion to piston is given by a slider-crank mechanism, where a man will be cycling to give the crank a rotary motion.

DISSERTATION OF MICRO-PROJECTS

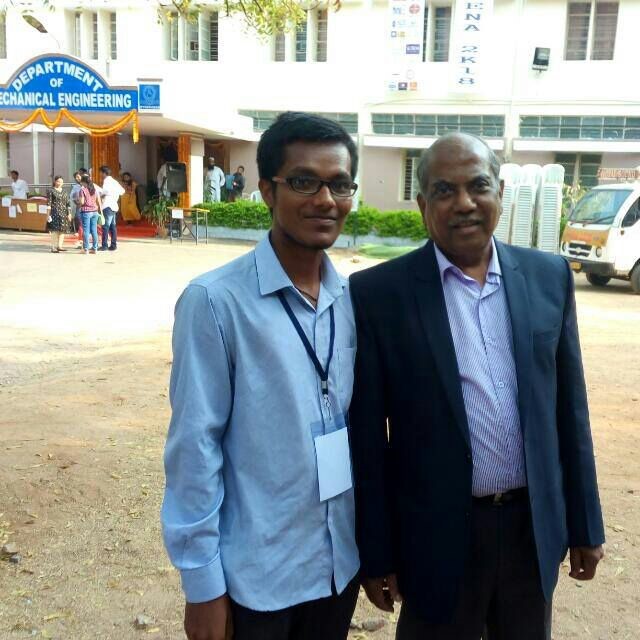

With loads of enthusiasm students of Mechanical Engineering have revolutionised many projects using advanced techniques in the field of manufacturing and technology such as “pesticide sprayer powered by bicycle, flexible agricultural sprayer, electric bicycle”. This event was conducted on April 20, 2018. 2nd year students presented their prototypes in the presence of honourable guest Dr.Y.V.D.RAO , professor of Mechanical Engineering, BITS-PILANI, Hyderabad campus . The best projects were rewarded cash prizes Rs 3000, Rs2000 and Rs1000 for first, second and third places.

The students of mechanical II –year , bagged 2nd prize for exhibiting their project “ TREAD MILL CYCLE” in “CONSORTIUM” , a national level technical feast conducted at IARE on 2nd & 3rd of November 2017.

SAE TIER – II

Students of MLRIT participated in SAEISS, Student Convention Tier-II Divisional Level Competition at CMRCET, Hyderabad and bagged prizes in “Aero Modelling and Animation”, “CNC Milling” and “How things work”.

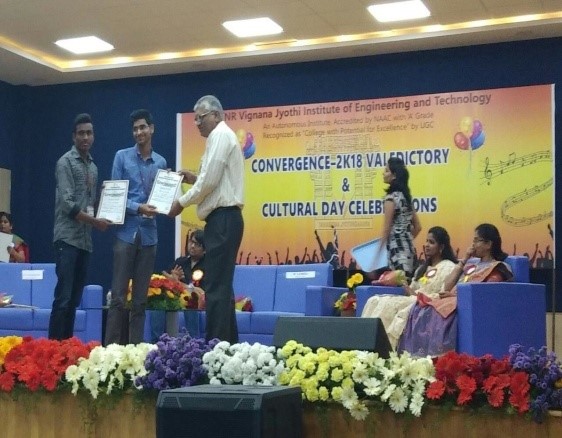

Rajeev and Varun , the students of mechanical II –year , bagged 2nd prize for PAPER PRESENTATION for the project “ VOICE CONTROLLED CAR” in “CONVERGENCE-2K18” , A national level technical feast conducted at VNR-VJIET held on 5th to 7th February 2018

Student of II year, Mechanical Engineering Ms APURVA was awarded 2nd prize for participating in the inter college elocution competition , topic KILL THE CANCER organized by ISKCON, Kukatpally , established in the year 1966 , ISKCON is an international movement spread across six continents with more than 800 centers across the globe .This competition was held at MALLA REDDY INSTITUTE OF PHARMACY

The students of mechanical engineering department bagged runner up prize for their mini project TRADE MILL CYCLE at national science fare 2018 held at MLRIT ON 20TH February, 2018 Which was conducted by the department of aeronautical engineering.

Harish student of 2nd year Mechanical bagged first prize in Osmaina university for paper presentation on the topic Flexible agriculture spray conducted on 9th march 2018.

Student of 2nd year mechanical harish, bagged first prize in Narsimhareddy engineering college for paper presentation on the topic flexible agriculture spray conducted on 28th march2018

Students of mechanical bagged 1st prize for startup JAM in national level innovation summit (PRERNA-2018) conducted by ministry of skill development and entrepreneurship at advanced training institute , government of India held on 11 APRIL 2018

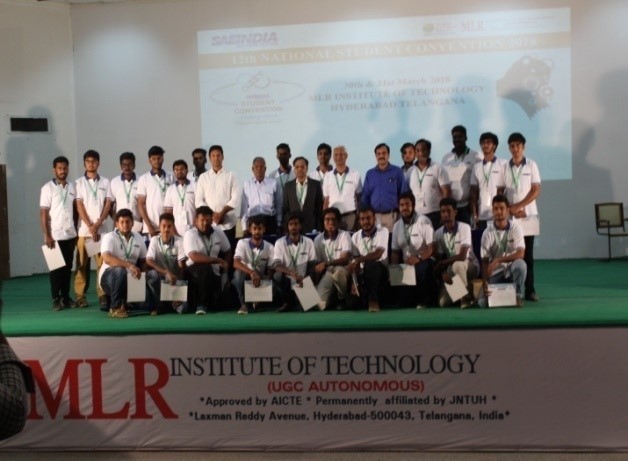

SAE TIER III – NATIONAL EVENT AT MLRIT

SAE India Convention at MLRIT egged students on to hone problem solving skills

SAEINDIA is a professional engineering society whose membership represents practically every engineering and scientific discipline. Its members combine their specialized abilities to further advance the research, development, design, manufacture and utilization of vehicles which operate on land, water, air and space.

Marri Laxman Reddy Institute of Technology organized a two-day national-level SAE INDIA student convention at its campus where 1600 students from across the country showcased their skills in various events. The event threw a challenge at the participating students in design, fabrication and problem-solving and how they react to a practical problem using their theoretical knowledge. It had 35 regular and 15 surprise events where they were judged by the industry experts. Mr Sriraman, Chairman, SAE India Southern Section was the distinguished guest along with Prof T. Papi Reddy, Chairman, TSCHE as chief guest of the event. Dr. Mr Y. Srinivas Rao, vice-chair SAEISS Hyderabad Division and Mr N. Bala Subramanian Ex- chairman, SAEISS and Vice President, Renault Nissan Business Centre of India represented the industry and guided the students. Theme of the event is to expose the local students to global practical challenges. It was a learning experience for faculty and students as they got an opportunity to interact with the industry heads on this event.

Students from various colleges who participated with great zeal bagged best performance awards and certified from honorable dignitaries on the day of valediction.

BAJA SAE INDIA 2017

Team Furious 17, under MLRIT Collegiate Club has participated in BAJA SAE Virtuals.

|

S.No |

Name |

College Reg. |

|

1 |

N.Mahesh ( Captian ) |

14R21A03F1 |

|

2 |

R.Sai Revanth Varma |

14R21A0347 |

|

3 |

K RAM |

15R21A03D2 |

|

4 |

VISHAL VISHWAKARMA |

13R21A0356 |

|

5 |

PAVAN KALYAN.S |

15R21A03F7 |

|

6 |

K.S RAMA KRISHNA |

15R21A0329 |

|

7 |

PRASHANTH PAMU |

15R21A03E6 |

|

8 |

RAJAPPAN ADARSH |

14R21A03G3 |

|

9 |

SATISH VARMA I |

15R21A0327 |

|

10 |

T RAJASHEKAR |

15R21A0355 |

|

11 |

B VAIBHAV |

15R21A03C0 |

|

12 |

G SAIDEEP |

14R25A0307 |

|

13 |

P. MANOJ KUMAR |

14R21A03F4 |

|

14 |

CH. MANEESHA |

15R21A03C4 |

|

15 |

T. PAVAN RAAJ |

13R21A0349 |

|

16 |

A.TARUN PAUL |

14R21A0302 |

|

17 |

M. SRI NAYAN |

14R21A03F0 |

|

18 |

P.RAHUL JOSHUA |

13R21A0341 |

|

19 |

P.ANKITHA |

15R21A03E8 |

SUPRA SAE INDIA 2016

XTREME RIDERS2K16 under MLRIT Collegiate Club participated in SAESUPRA 2016 and placed at 60th rank nationwide.

The members of the team XTREME RIDERS2K16 consists of 23 members and have participated in the prestigious event known as SUPRA which is conducted by SAE INDIA. SUPRA SAEINDIA is a national level design competition organized by Society of Automotive Engineers (SAE) – India. Target of designing and manufacturing a Formula 3 race car. Expected to build, test and validate the race car restrained under manufacturing standards. The whole event was sponsored by the India’s leading automobile company MARUTI SUZUKI and the event was held at BUDDH INTERNATIONAL CIRCUIT in Noida, which is the only international circuit in India.